Popular reactive power compensation cabinet

2017-08-23

admin

The following contents take 400V reactive power compensation cabinet as an example to give you a general introduction of reactive power compensation cabinets and components in cabinets. This content can be used as a basic knowledge for salesperson of reactive power compensation products.

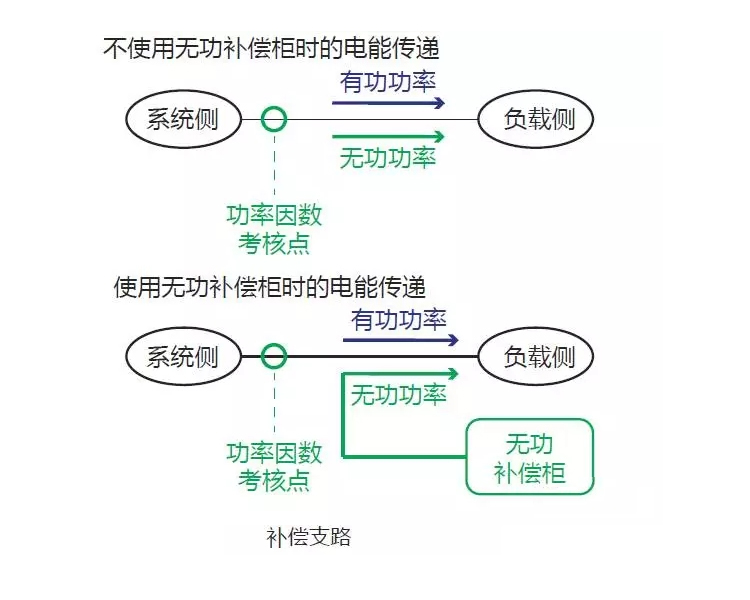

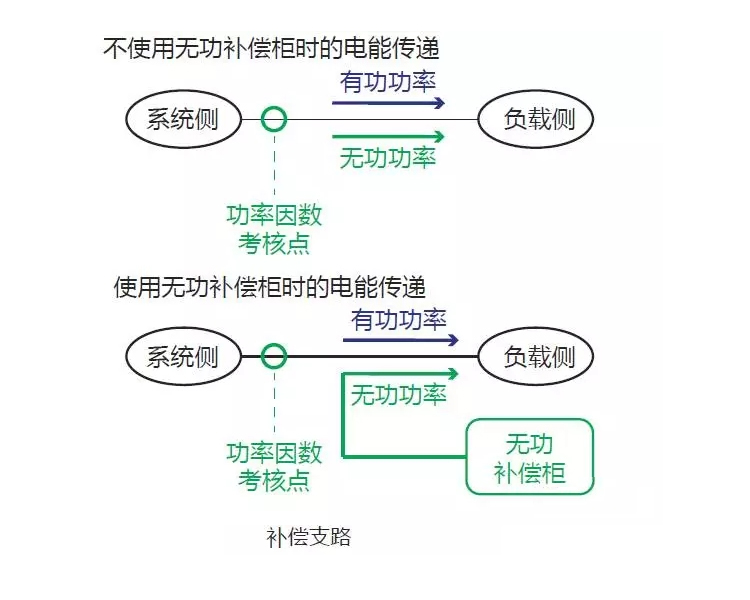

A. reactive compensation cabinet?

In the 400V system, the reactive power compensation cabinet is a set of low-voltage cabinet for providing reactive power to the distribution system.

Remember two points:

1) it's a low pressure cabinet

2) it provides reactive power for the user's electrical equipment.

Another saying: a device that corrections the power factor of the system. (this statement sounds tall)

As a complete set of equipment, the reactive power compensation cabinet consists of the cabinet and the components in the cabinet. It mainly includes the following elements:

1) main switch

2) overvoltage protection element

3) protection components

4) switch off switch

5) reactor

6) capacitor

7) controller

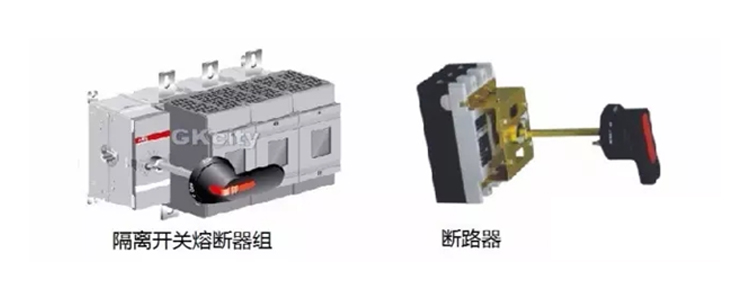

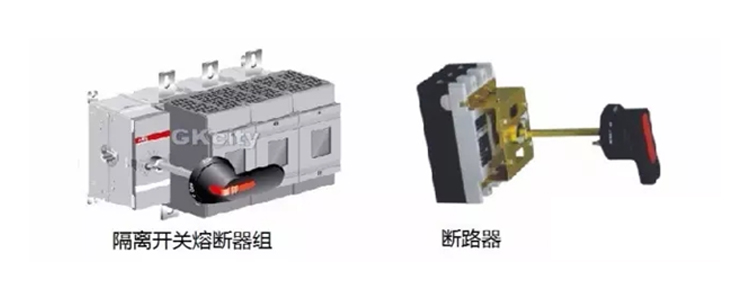

B. master switch

Every reactive compensation cabinet, as an independent device, has a main switch to connect the compensation device to the bus. At the same time, it plays a protective role in the short circuit fault in this cabinet.

The main switch is often used as a fuse switch or a circuit breaker.

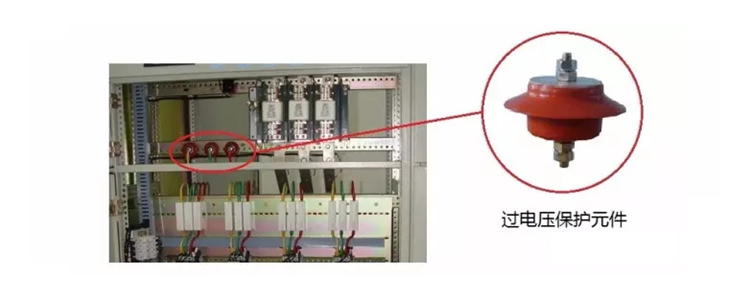

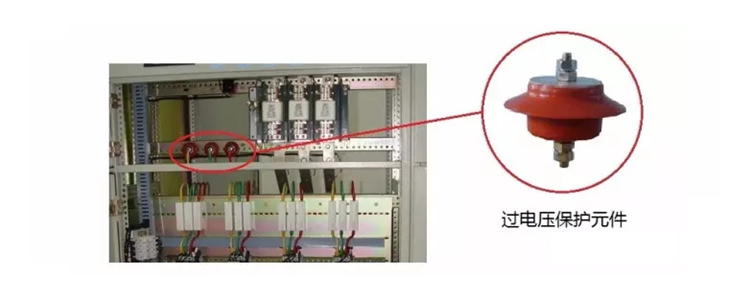

C. overvoltage protection element

The effect of Overvoltage on the equipment in the cabinet is reduced, and the damage to the components in the cabinet is prevented by overvoltage.

Every reactive compensation cabinet is made up of several reactive compensation branches. The branches are included: protection elements, switching switches, reactors, and electric capacitors.

D. protection element

It protects the components and faults on the compensation branch.

The protective components on the branch are often used as fuses, and the parameters need to be matched with the capacitor on the branch.

E. switching switch

The function of the switch is to connect the capacitor and reactor on the compensation branch to the system or to exit the component of the system.

The capacitance reactance is connected to the system, that is, the constant input of the capacitor; the capacitance reactance is removed from the system, that is, the commonly said capacitor is excised.

PS: when capacitors are put into operation, there is inrush current, which is the basic characteristic of capacitor input. Therefore, switching switch has another function, which is to reduce the inrush current of capacitors.

The common capacitor switching switches are:

Capacitor special contactor

Thyristor switch

Composite switch

Capacitor special contactor

Remember, it must be a special capacitor.

The contactor of the capacitor is more than one pair of contacts of the conventional contactor, and the resistance value in the circuit is larger than that in the loop, leading to the reduction of the inrush current of the capacitor.

Advantages: less fever during operation

Shortcomings: Although the capacitor inrush is effectively limited, the flow value is still larger.

Thyristor switch

This device is called more, often seen or heard of thyristor switch, non-contact switch, regulator all refers to it.

The switching of the thyristor is used to realize the switching of the capacitor.

Advantages: the "zero crossing" can be realized, that is, the flow of capacitor can be limited to the minimum.

Shortcomings: a large amount of heat.

Thyristor is very sensitive to heat, and the superheat will damage to thyristor. In addition, emitting a lot of heat will also cause a significant increase in the temperature of the reactive power compensation cabinet, and the high ambient temperature has great influence on the life of the capacitor.

Therefore, when using the thyristor switch, we must pay attention to the heat dissipation.

The heat dissipation of the 1. thyristor switch is often done by its own cooling fan. When the temperature of the thyristor is higher than the limit, the fan is started; when the temperature is lower to the limit, the fan stops working. When the temperature rises above the dangerous temperature, the thyristor switch protection system will leave the thyristor out of the working state.

2. the heat dissipation of the reactive power compensation cabinet.

Composite switch

A composite switch is a product that combines the advantages of a thyristor switch and a contactor, which is composed of a thyristor and a mechanical contact.

The switching of capacitors is accomplished by thyristor, which ensures the zero crossing switching of capacitors. After the capacitor is put into operation, the mechanical contact is used as the conduction circuit to avoid the heat generated by the thyristor for long term operation.

F. reactor

The reactor is the companion of the capacitor, which has appeared together in many times. As an important component in the reactive power compensation cabinet, it must be understood.

The reactor has two main functions:

1. suppression of capacitor inrush

2. suppression harmonics

To know the appearance of a common reactor, see the picture below.

Our common reactor has two types of wire wound and foil.

According to the different material, the wire wound reactor has copper wire and aluminum wire, and the same reason, there are two kinds of copper foil and aluminum foil.

Reactors are usually protected by over temperature. They have a pair of contacts (usually closed much). When the reactor is over heated, the contacts are open, which can be used to remove the reactor from the system.

The parameters often described by the reactor are "reactance".

The reactor that is specially used to suppress the flow of capacitors is not more than 1%.

The reactance rate is based on the number of main harmonics in the system. For example: to suppress the influence of the 5 and 7 harmonics, the common 5.6%, 6%, 7% reactance rates, the 3 harmonic suppression, and the common 12%, 13%, 14% reactance rates.

G. capacitor

The main components of the reactive power compensation cabinet. Because of the existence of capacitors, the reactive power compensation cabinet is often called "capacitor cabinet".

In the low pressure system, our common capacitors are self-healing capacitors (made of metallized films).

Dry capacitor

According to the difference in the internal filling agent of the capacitor, several kinds of different kinds can be divided. For example, we often hear the word "dry capacitor".

Oil immersed capacitor, as the name implies that filling agent is liquid, the defect of liquid is leakage risk, and oil is flammable.

The dry capacitor has solved the above disadvantages of the oil immersed capacitor, which is usually filled with filled resin and inert gas.

Shape and installation

There are many shapes and sizes of capacitors, such as oval, circular, square and so on.

Different configurations determine the different installation methods.

Capacitor terminal

Wiring terminals are common with screw and European terminals, such as drawings.

Screw connection, the contact area is big, the connection is firm. The wiring column is exposed to the outside, usually with a protective cover.

European terminal with exquisite structure and small contact area. When the most common fault occurs, the terminal terminal is loose, and the contact point heat causes the terminal to burn out.

Explosion-proof device

In order to prevent the explosion of capacitors, explosion-proof devices are usually installed.

Discharge resistance

The capacitor itself is a energy storage element. When the capacitor is out of operation, its own charge needs to be released, and the discharge resistance is used to complete the capacitor. The discharge resistance can be built outside and can be built in. The discharge voltage is required below 75V within the prescribed time.

More about capacitor knowledge, please pay attention to the other content of the micro signal "Zheng ER technology".

H. power factor controller

The power factor controller is the control center of the reactive power compensation cabinet, and it is the core of the automatic switching of the compensator (compensation branch).

Basic working principle

Power factor controller monitoring system is lack of reactive power or power factor index, control capacitor (compensation branch) automatic switching, so as to adjust the power factor to be qualified.

The power factor controller can be understood from the following aspects

1. control parameters

The power factor controller is based on the parameters of the power factor? The lack of reactive power? Or something else?

Common power factor, reactive component, and a variety of parameters are mixed.

2. compensation method

Three phase complements and phase separation compensation.

The three-phase co compensation means to send a command, at the same time the system A, B, C three-phase reactive vacancy compensation.

Compensation refers to issue a command, the system can only A, B, C three in one phase of vacancy compensation, which can realize the independent control of reactive power compensation for each.

The hybrid compensation means that the three phase publication and phase separation compensation can be realized simultaneously.

3. compensation control output type and loop number

The controller usually has two output command types, one is the contact point output, the other is mainly used for contactor control, the other is level output, which is mainly used to control thyristor switch and compound switch.

The number of output circuits of the controller determines the number of compensation branches that can be controlled by a controller. There are 6 roads, 12 roads and 18 roads.

4. controller monitoring parameters

As an intelligent device, many power factor controllers can monitor a lot of electrical parameters at the same time.

For example, current, voltage, reactive power, harmonic distortion rate and so on.

5. The monitor interface of the controller

The common controller interface consists of digital display and liquid crystal display.

6. record of protection function and fault information

As the intelligent equipment in the reactive power compensation cabinet, the power factor controller usually has a perfect protection function to ensure the safe operation of the reactive power compensation cabinet. Such as overvoltage, undervoltage, over temperature protection and so on.

The fault information can be recorded in full, and the included time mark is recorded.

7. data sharing

As an intelligent device, its data can be shared to third parties.

That is: whether it has a standard communication interface and whether the communication protocol is open.

Again, it is often heard that the device has a RS485 interface, is it a Modbus communication protocol.

For each equipment in the type of low voltage cabinet, we all have to consider the following problems, and the reactive power compensation cabinet is no exception.

1) cabinet and cabinet size

The cabinet type of the reactive power compensation cabinet and the low pressure switch cabinet.

2) measurement system

For a complete set of equipment, the instrument is generally required to measure the electrical parameters.

That is, usually the reactive power compensation cabinet will configure the power meter.

3) heat dissipation system

The heat dissipation of the reactive compensation cabinet must be done well, otherwise the overheating of the temperature in the cabinet will directly cause the damage of the capacitor.

The heat dissipation can be achieved by the conventional temperature controller + exhaust fan and the special air-conditioner of the switch cabinet.

4) the top of the cabinet is connected to the main bus, bus switch cabinet top cabinet

Why when it comes to specified bus? This is a place that is easily overlooked by some people.

If you are a low-voltage cabinet factory, the project all cabinets are done by your family, including the reactive power compensation cabinet, then the provisions of the bus nature is provided with complete cabinet factory.

If the reactive power compensation cabinet is provided by third parties alone, the general reactive power compensation cabinet at this time do not contain provisions and provisions of bus connection to the bus line of the main switch cabinet. At this point the user needs to be aware that this part of the device should not be missed.

5) the two wiring of this equipment and the external

The other wiring of the reactive power compensation cabinet is handed over to the technical engineer to deal with. As a salesperson, do not pay attention to such details, because the content needs many words to make it clear.

Through the above content, everyone is basically clear of the reactive compensation cabinet. It is a low voltage cabinet combined with a large number of power components. Therefore, I suggest to users that the main components in reactive power compensation cabinet, such as capacitors, reactors, power factor controllers, switching switches, etc., should be selected after the brand and specifications are selected, and the assembly of other components and equipment will be handed over to the whole plant. In this way, the quality of the components is controlled and the quality of the complete set of cabinet is guaranteed.

Return

JKWF Hybrid reactive power compensation controllerJKWF series Hybrid reactive power compensation controller integrates the functions of Monitoring grid ,harmonic protection, compensation and fault warning...

JKWF Hybrid reactive power compensation controllerJKWF series Hybrid reactive power compensation controller integrates the functions of Monitoring grid ,harmonic protection, compensation and fault warning... YBYKXB Resist harmonic intelligence switchYBYKXB Anti harmonic intelligent switch is Application of advanced compensation measurement and control technology,All electronic, intelligent, high performance dynamic compensation switch....

YBYKXB Resist harmonic intelligence switchYBYKXB Anti harmonic intelligent switch is Application of advanced compensation measurement and control technology,All electronic, intelligent, high performance dynamic compensation switch.... YBYCRz CapacitorsYBYCRz series cylinder type self-healing low voltage power capacitor,use German treofan material, with the most advanced manufacturing processes and equipment produced....

YBYCRz CapacitorsYBYCRz series cylinder type self-healing low voltage power capacitor,use German treofan material, with the most advanced manufacturing processes and equipment produced.... Quality assurance of power quality componentsRigorous, precise quality inspection is the focus of the work of AIA Yi, from the beginning of the screening test material to assembly line inspection, installation testing, etc. process through the digital monitoring strictly, each process into products...

Quality assurance of power quality componentsRigorous, precise quality inspection is the focus of the work of AIA Yi, from the beginning of the screening test material to assembly line inspection, installation testing, etc. process through the digital monitoring strictly, each process into products... YBYTU800 Harmonic monitorThe product integrates data collection, statistics, communications, power grid harmonic analysis, harmonic alarm and other functions....

YBYTU800 Harmonic monitorThe product integrates data collection, statistics, communications, power grid harmonic analysis, harmonic alarm and other functions.... Quality assurance of harmonic monitoring platformRigorous, precise quality inspection is the focus of the work of AIA Yi, from the beginning of the screening test material to assembly line inspection, installation testing, etc. process through the digital monitoring strictly, each process into products...

Quality assurance of harmonic monitoring platformRigorous, precise quality inspection is the focus of the work of AIA Yi, from the beginning of the screening test material to assembly line inspection, installation testing, etc. process through the digital monitoring strictly, each process into products... The power distribution system of drilling platform has been powered by generators, and has been powered by electricity. Now, the power supply is provided by the power grid. Because of the large amount of harmonic currents generated by DC motor and frequency conversion motor, dynamic reactive power compensation and harmonic control are needed. The frequent start and stop of the motor causes great interference to the power grid

The power distribution system of drilling platform has been powered by generators, and has been powered by electricity. Now, the power supply is provided by the power grid. Because of the large amount of harmonic currents generated by DC motor and frequency conversion motor, dynamic reactive power compensation and harmonic control are needed. The frequent start and stop of the motor causes great interference to the power grid The main load equipment is the frequency converter. Because of the large harmonic current (especially the 5 and 7 harmonics) produced by the load, the voltage and current of the system will be distorted, which will affect the normal operation and safety production of the equipment. The input side of the inverter is a nonlinear rectifier circuit, which affects the waveform of the power supply. The output side voltage, current, non sinusoidal or incomplete sine wave are rich in harmonics.

The main load equipment is the frequency converter. Because of the large harmonic current (especially the 5 and 7 harmonics) produced by the load, the voltage and current of the system will be distorted, which will affect the normal operation and safety production of the equipment. The input side of the inverter is a nonlinear rectifier circuit, which affects the waveform of the power supply. The output side voltage, current, non sinusoidal or incomplete sine wave are rich in harmonics. Container terminal loads are mostly cranes, which are impulse loads, with large amplitude and obvious voltage drop. Especially during the whole process, flickering and voltage collapse are very obvious. The power factor of the motor is very low during starting up. This impulse reactive power will make the grid voltage fluctuate violently, even even the users connected to the same power grid can not work normally.

Container terminal loads are mostly cranes, which are impulse loads, with large amplitude and obvious voltage drop. Especially during the whole process, flickering and voltage collapse are very obvious. The power factor of the motor is very low during starting up. This impulse reactive power will make the grid voltage fluctuate violently, even even the users connected to the same power grid can not work normally. In the port industry, the loading and unloading bridges and the belt conveyer are widely adopted by AC frequency converter and DC rectifier. This kind of load is a typical nonlinear load...

In the port industry, the loading and unloading bridges and the belt conveyer are widely adopted by AC frequency converter and DC rectifier. This kind of load is a typical nonlinear load... Through the effective protection of the harmonic control after the safe use of transformers, power distribution cabinets, and equipment, prolong the service life of the equipment; the utility grid device to produce additional power consumption is reduced; improve the efficiency of electricity charging equipment, battery charging protection in the process of safety; greatly reduces the harmonic current into the power grid, to avoid the interference of adjacent power supply system.

Through the effective protection of the harmonic control after the safe use of transformers, power distribution cabinets, and equipment, prolong the service life of the equipment; the utility grid device to produce additional power consumption is reduced; improve the efficiency of electricity charging equipment, battery charging protection in the process of safety; greatly reduces the harmonic current into the power grid, to avoid the interference of adjacent power supply system. After the active filter is put into operation, the total current distortion rate is reduced to 0.75%. The quality of the power grid has been greatly improved, which effectively protects the normal operation of the equipment.

After the active filter is put into operation, the total current distortion rate is reduced to 0.75%. The quality of the power grid has been greatly improved, which effectively protects the normal operation of the equipment. The total current distortion rate is reduced to 4.78%, the distortion rate of each subharmonic is within 1.5%, and the waveform of the non sinusoidal wave before the treatment is a sine wave. It can be seen that after the input of the filter, the harmonic of the system has been well suppressed, improving the reliability of the power supply system, eliminating the hidden trouble of the influence of the system harmonic on the communication system, and receiving good results.

The total current distortion rate is reduced to 4.78%, the distortion rate of each subharmonic is within 1.5%, and the waveform of the non sinusoidal wave before the treatment is a sine wave. It can be seen that after the input of the filter, the harmonic of the system has been well suppressed, improving the reliability of the power supply system, eliminating the hidden trouble of the influence of the system harmonic on the communication system, and receiving good results. Professional engineers provide comprehensive and systematic technical training and operation guidance for customers, including fault diagnosis, equipment commissioning, equipment maintenance, product selection, and overall solution, to meet diverse needs of different types of customers.

Professional engineers provide comprehensive and systematic technical training and operation guidance for customers, including fault diagnosis, equipment commissioning, equipment maintenance, product selection, and overall solution, to meet diverse needs of different types of customers. To understand the more comprehensive electrical products and model parameters of YBY electric, welcome to download the album of related products.....

To understand the more comprehensive electrical products and model parameters of YBY electric, welcome to download the album of related products..... Download the product certificate from YBY electric, product patent certificate, 3C certification, CQC and other certificates…....Field service application form Service application form Complaint & recommendation platform I want to buy

Download the product certificate from YBY electric, product patent certificate, 3C certification, CQC and other certificates…....Field service application form Service application form Complaint & recommendation platform I want to buy Related products and services, the company according to your actual needs in twenty-four hours or an agreed time to provide on-site technical service personnel. As required, please try to provide detailed information so that we can better serve you.

Related products and services, the company according to your actual needs in twenty-four hours or an agreed time to provide on-site technical service personnel. As required, please try to provide detailed information so that we can better serve you. the company according to your actual needs in twenty-four hours or an agreed time to provide on-site technical service personnel. please try to provide detailed information so that we can better serve you.

the company according to your actual needs in twenty-four hours or an agreed time to provide on-site technical service personnel. please try to provide detailed information so that we can better serve you. When you have any comments and suggestions about our products, packaging, transportation and customer service service, can be put to us, we will be the first time response, give you a professional, efficient and satisfactory service. As required, please try to provide detailed information so that we can better serve you.

When you have any comments and suggestions about our products, packaging, transportation and customer service service, can be put to us, we will be the first time response, give you a professional, efficient and satisfactory service. As required, please try to provide detailed information so that we can better serve you.